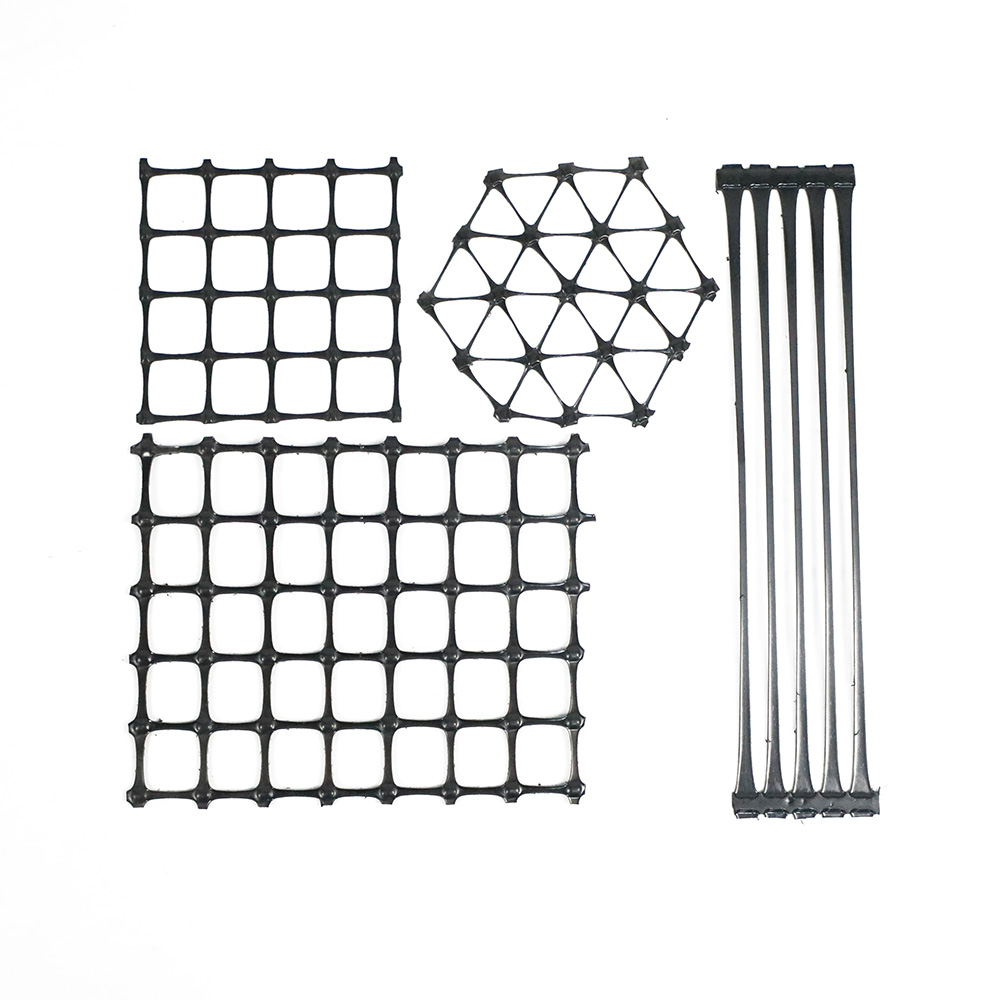

Steel plastic welding geogrid with strong bearing capacity for road pavement railway basement tunnel slope

Product Details

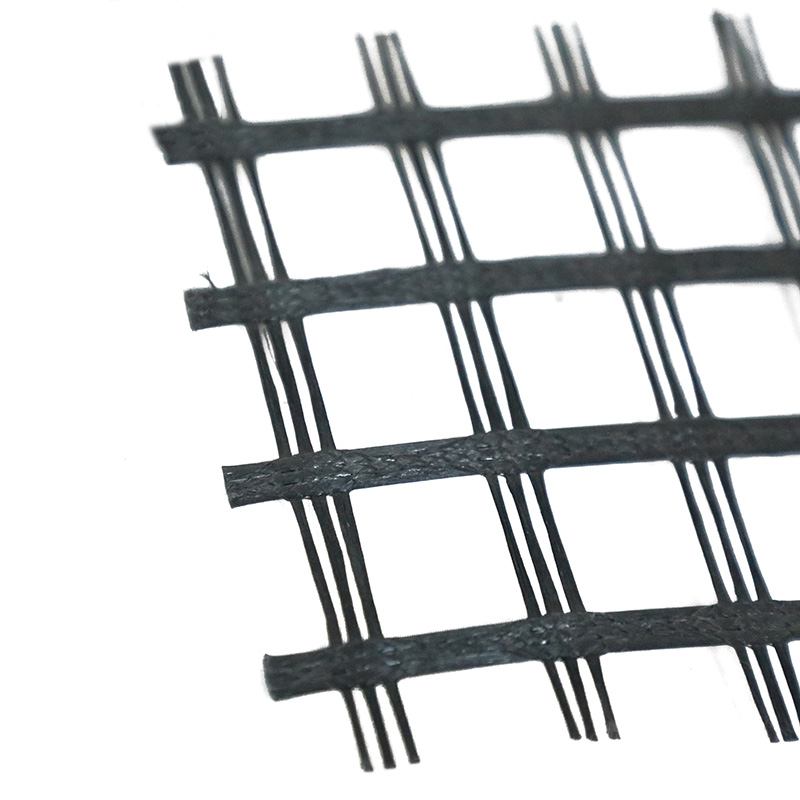

Fiberglass geogrid is an excellent geosynthetic material used for road reinforcement, old road reinforcement, reinforcing road base and soft soil base. Fiberglass geogrid is a semi-rigid product made of high strength alkali-free fiberglass through the international advanced warp knitting process and coated by surface treatment. It has high tensile strength and low elongation in both warp and weft directions, and has excellent properties of high temperature resistance, low cold resistance, aging resistance, corrosion resistance, etc. It is widely used in asphalt pavement, cement pavement and roadbed reinforcement and railroad roadbed, dam slope protection, airport runway, sand control and other engineering projects.

The main component of fiberglass is: silicon oxide, is inorganic materials, its physical and chemical properties are extremely stable, and has a high modulus, wear resistance and excellent cold resistance, no long-term creep; good thermal stability; mesh structure so that the aggregate embedded lock and limit; improve the load-bearing capacity of the asphalt mixture. Because the surface is coated with special modified asphalt, it has two compound properties, both the excellent properties of fiberglass and the compatibility with asphalt mixture, which improves the abrasion resistance and shear resistance of geogrid.

Features of fiberglass geogrid products

The product has high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance, long life, etc. It can be widely used in the old cement pavement, airport runway maintenance, embankment, river bank, slope protection, road and bridge pavement enhancement treatment and other engineering fields, which can give pavement enhancement, reinforcement, prevent pavement rutting fatigue crack, hot and cold expansion crack and reflection crack below, and can Dispersion, prolong the service life of pavement, high tensile strength low elongation, no long-term creep, good physical and chemical stability, good thermal stability, fatigue cracking resistance, high temperature rutting resistance, low temperature shrinkage cracking resistance, delayed reduction of reflection cracks.

Fiberglass geogrid construction process

(1) First of all, accurately put out the slope line of the roadbed, in order to ensure the width of the roadbed, each side is widened by 0.5m, the drying of good substrate soil for leveling after using 25T vibratory roller static pressure two times, and then 50T shock pressure four times, the uneven place with manual leveling.

(2) Laying 0.3m thick medium (coarse) sand, manual with mechanical leveling, 25T vibration roller static pressure two times.

(3) laying geogrid, geogrid laying bottom surface should be flat, dense, generally should be laid flat, straight, no overlap, no curl, kink, two adjacent geogrid need to lap 0.2m, and along the roadbed lateral geogrid lap part every 1m with No. 8 wire for interpolation connection, and in the laid grids, every 1.5-2m with U-nails fixed to the ground.

(4) the first layer of geogrid paved, began to fill the second layer of 0.2m thick in (coarse) sand, the method: car sand to the site unloaded on the side of the roadbed, and then use the bulldozer to push forward, first 2 meters on both sides of the roadbed after filling 0.1m, the first layer of geogrid folded up and then filled with 0.1m in (coarse) sand, prohibit both sides to the middle of the filling and advance, prohibit all kinds of machinery in the absence of This can ensure that the geogrid is flat, without drums and wrinkles, and after the second layer of medium (coarse) sand is flattened, the level measurement should be carried out to prevent uneven filling thickness, and the 25T vibratory roller should be used for two times after the leveling is correct.

(5) the second layer of geogrid construction method with the first layer of the same method, and finally fill 0.3m in (coarse) sand, filling the same method as the first layer, with 25T roller static pressure two times, so that the roadbed substrate reinforcement is completed.

(6) in the third layer of (coarse) sand crushed, along the line of longitudinal road on both sides of the slope laid geogrid two, lap 0.16m, and connected in the same way, and then start earth construction operations, laying geogrid for slope protection, each layer must be measured out of the edge of laying, each side to ensure that the slope repair geogrid buried in the slope 0.10m.

(7) For every two layers of soil filled, i.e. 0.8m in thickness, a layer of geogrid should be laid on both sides at the same time, and then so on until it reaches the surface of the road shoulder.

(8) after the roadbed is filled, timely slope repair, and dry stone protection at the foot of the slope, the section of the roadbed in addition to widening 0.3m on each side, and reserved 1.5% of the sinkage.