As the surface of the steel-plastic geogrid extends into a regular rough pattern, it is subjected to enormous stress resistance and friction with the fill, which limits the shearing, lateral compression and uplift of the foundation soil as a whole. Due to the high stiffness of the reinforced soil cushion, it is conducive to the diffusion and uniform transmission of the upper foundation load, and is distributed on the underlying soft soil layer with good bearing capacity. So, what is the use of steel plastic geogrids on asphalt overlays?

Due to its excellent performance, after surface modification and coating treatment, the surface properties of steel and plastic have changed, the composite properties of steel have been improved, and the wear resistance and shear resistance of the matrix have been greatly improved.improve. The steel plastic geogrid produced by the steel plastic geogrid manufacturer can play an important role when applied to the asphalt overlay.

When the temperature is high, the surface of the asphalt pavement is soft and sticky; under the action of the vehicle load, the asphalt surface cannot return to its previous state. After the load is removed, plastic deformation occurs. Plastic deformation is formed under the influence of constant accumulation and repeated rolling of vehicles during estrus. In asphalt pavement, steel plastic geogrid can disperse stress and tensile stress, and form a buffer zone between the two. The stress is not changed suddenly but gradually, which reduces the damage of the asphalt pavement caused by the sudden change of stress. At the same time, the low elongation reduces the deflection of the road surface and ensures that the road surface will not undergo excessive deformation.

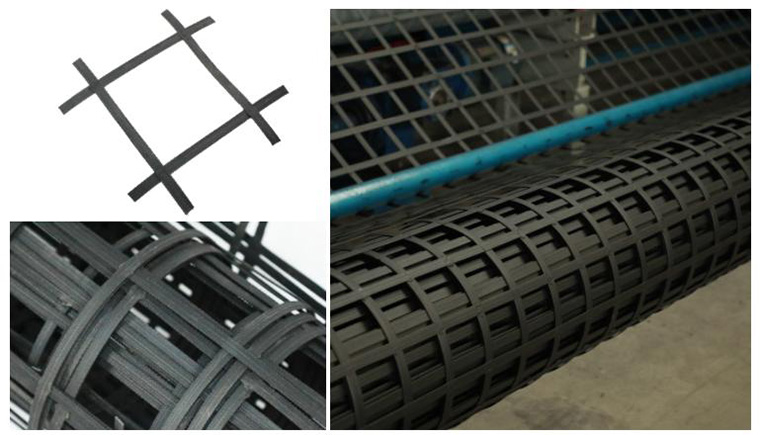

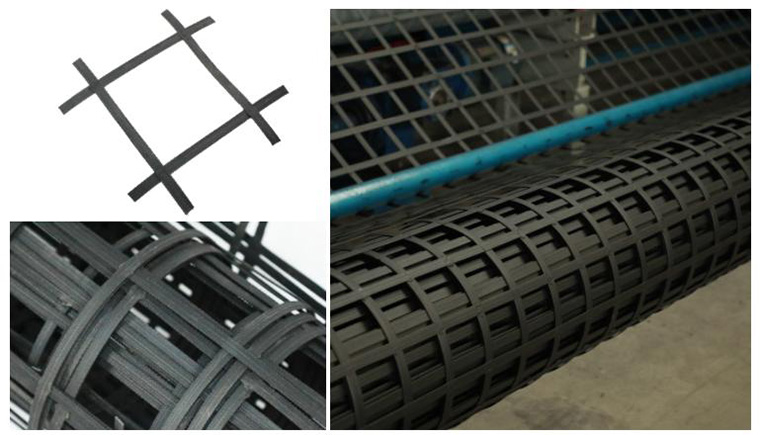

Steel plastic geogrid is a major geosynthetic material. It has unique properties and efficacy compared to other geosynthetics. Geogrids are often used for reinforcement of reinforced soil structures or composite materials. The steel-plastic geogrid is made of high-strength steel wire through special treatment, and is extruded into a composite high-strength tensile belt with rough embossing on the surface with additives such as polyethylene or polypropylene. This single belt is woven or clamped at a certain distance longitudinally and transversely, and its joints are welded by special reinforcement and bonding welding technology. It is a reinforced geogrid.

Post time:

Mar-29-2022